THE WORLD’S FINEST

Concrete Wine Tanks

Are Made In America

Why Concrete?

Concrete can be cast into any shape, offering winemakers both functional and expressive design options. Square and rectangular tanks maximize space efficiency and reduce cost per gallon—ideal for high-volume production. But organic shapes like eggs and amphorae have no corners, encouraging natural fluid circulation that you can actually observe. This promotes a healthier fermentation process and, ultimately, produces better, more expressive wine.

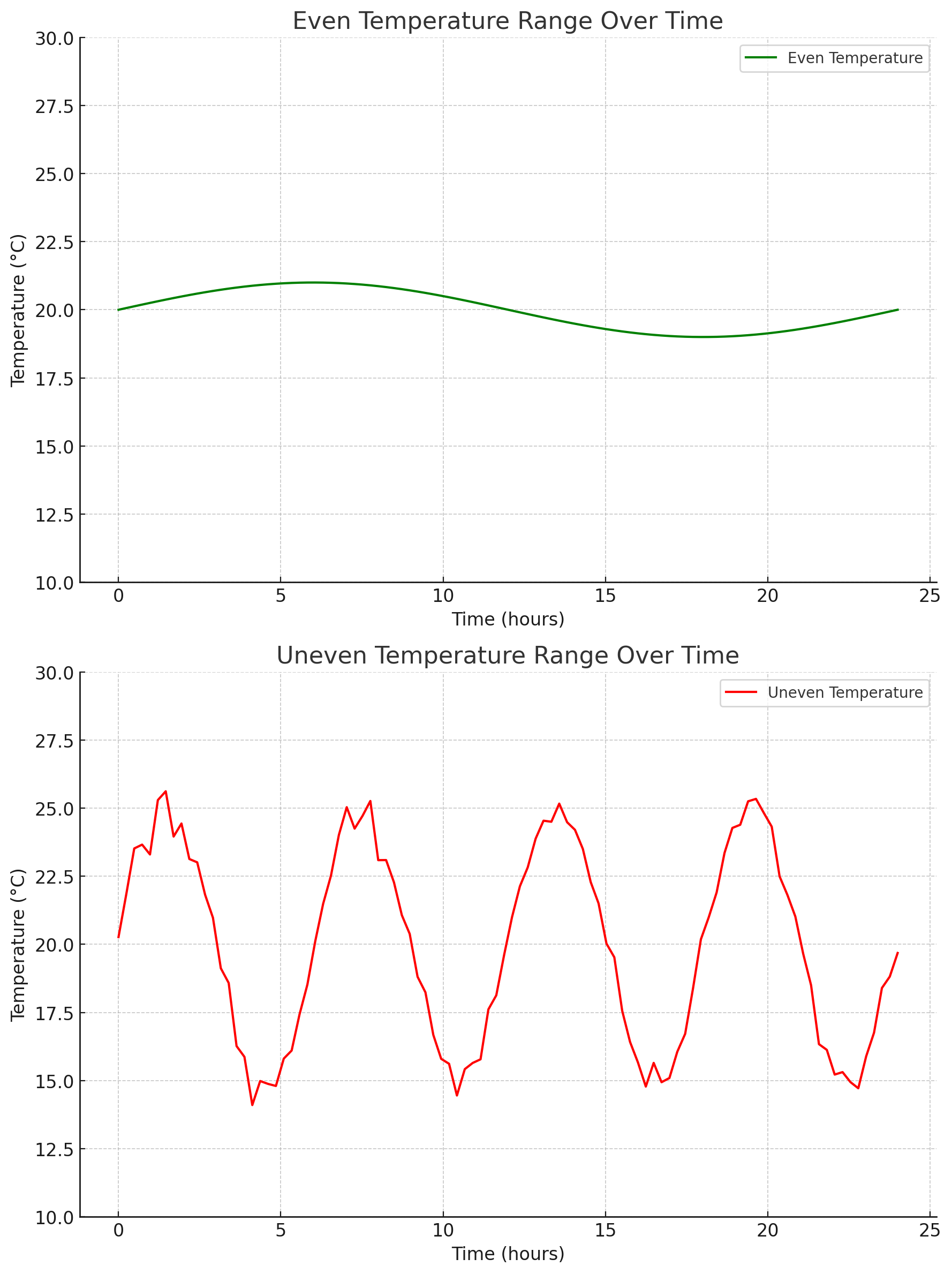

Concrete’s thermal mass insulates and helps maintain a stable fermentation temperature naturally. This steady environment prevents temperature spikes that can stress yeast or cause off-flavors. As a result, fermentation proceeds smoothly, preserving the wine’s aromatic integrity and allowing for a more controlled, consistent expression of fruit and terroir.

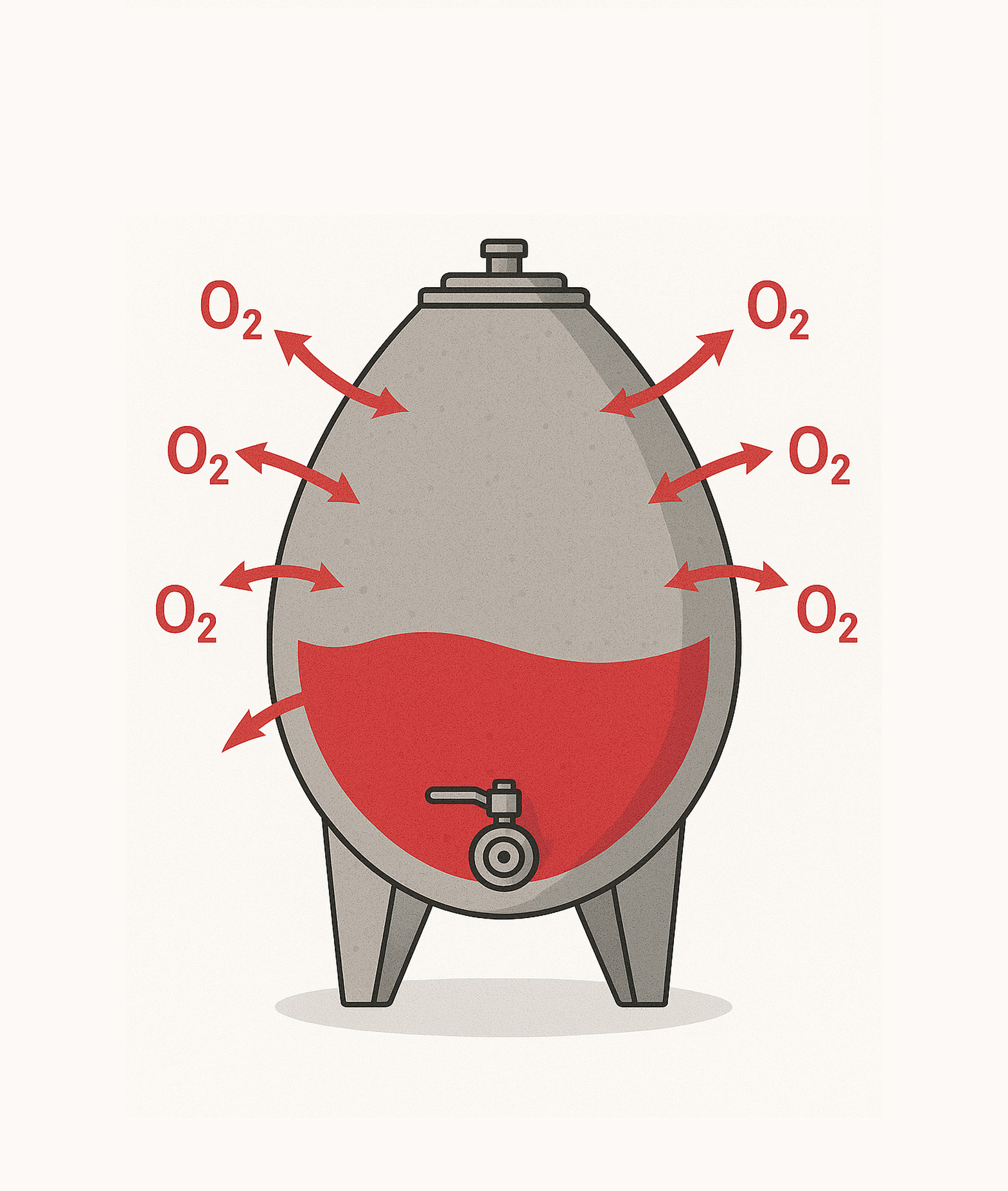

Fermenting wine in concrete allows subtle oxygen exchange, softening tannins and enhancing complexity—something stainless steel can’t provide. Unlike oak, concrete imparts no additional flavors, letting the true character of the grape shine. This makes it ideal for winemakers seeking fruit-forward purity, balance, and a more expressive, terroir-driven wine without the influence of oak.

Wine Business Monthly hosted the first Innovation + Quality conference, an exclusive gathering for ultra-premium wineries dedicated to the concept of using innovation to advance wine quality. 400 winemakers there performed a taste test comparing wines made in oak, stainless steel and concrete. Concrete won so convincingly that it was not necessary to count the votes.

Why Us?

No one else can offer you a ten-year guarantee against structural cracks and leaking, because no one else makes concrete wine tanks the way we do. Our tanks are engineered with a concrete layering system that is among our best innovations, because it renders our tanks more durable than any others.

Sonoma Cast Stone is the only manufacturer of concrete wine tanks in North America. When you purchase our tanks you are allocating your budget to quality and not to the fluctuating costs of overseas shipping and customs fees.

Our 50,000 sq-ft factory is packed with the tools and the talent to deliver one perfect tank–or dozens of them–on schedule and on budget. So whether you’re launching a new winery or just looking for something special to elevate your wine, Sonoma Cast Stone is the right choice.

Concrete NuBarrels are a key innovation in the wine industry. Your oak barrels may last a few years, but our NuBarrels last a few decades. They require significantly less space, they’re easier to clean and manage, they suffer less evaporation, and they’ll be yielding the luzury wine you only get from concrete long after those oak barrels have become a disposal problem.

The big advantage of the egg is of course, that oval shape. The shape allows for a natural convection of the lees all throughout fermentation, and this constant contact adds weight and complexity to the texture of our wines.

Gianna Kelly

Winemaker

Galerie

Concrete changes the perception of flavor. The texture and mouthfeel are affected due to the longer natural suspension of the lees in the juice. This affects the perception of acidity, which is crucial for flavor and aroma perception. [Concrete] is the best material to keep temperature homogenous in all levels of the winemaking process. (also) I perform battonage once a week in barrels, twice a week in stainless steel and just once a month in concrete to get the same result in wine.

Laura Diaz Munoz

Winemaker

Ehlers Estate

Concrete does a very good job of showcasing a wine’s true terroir. Oak can mask those distinctions, but concrete doesn’t add, remove, or mask anything. It lets the fruit shine through to be a true statement of the place it was grown. Concrete enhances the seamlessness and integration of flavours of a wine and is more robust and velvety on the mid-palate.

Michael Bartier

Winemaker

Okanagan Crush Pad

When we conduct in-house tastings with our team to compare Jordan’s chardonnay base wines made in both concrete and stainless steel, the difference is remarkable. When the grapes are fermented in the concrete egg, the vessel adds dimension, brightness, freshness and texture—exactly what we want in our chardonnay.

Maggie Kruse

Winemaker

Jordan Winery

It takes one 75-year-old oak tree to produce two barrels for wine use and those barrels have a usable life of three to five years. If we can make better wine while using concrete with its low carbon footprint in production and an unlimited lifespan of use, the result is a potential huge value in reducing our carbon footprint.

John Williams

Owner

Frog’s Leap

…the sizing (of the egg tanks) is perfect, the fact that we can do 470 gallons on one footprint and have that be a fermenter that takes us from fermenting all the way through aging and the final point of blending before bottling is great…

Brian Rudin

Winemaker

Echolands

Concrete tanks are an amazingly old matrix but they’re also very 21st century. We were surprised by how the red wine evolved during fermentation, and we’d like to do more of it. The (nine tower) tanks we purchased (from SCS) are really doing very well for us. I’ve enjoyed the innovation of having the temperature control embedded in the sides (of the tower tanks). They’ve been surprisingly easy to clean and maintain.

Harry Hansen

Winemaker

Sterling Vineyards

…for me the [embedded glycol] temperature control is a big factor and then the wow factor to see the cool showpiece in the winery…

Kyle Anderson

Winemaker

Formerly, Cliff Lede

I’m already blown away by the color density from concrete versus stainless steel.

Chris Russi

Winemaker

Formerly, Thomas George Estate

I wanted to tell you that we are thrilled with the wines we produced using the egg. We were able to get 4 turns of the fermenter, utilizing it for a Rose, BDX Field Blend, Cab Sauv, and a WR. Currently, we are aging some Mouvedre in the tank and are very happy with how the wine is evolving compared to its stainless steel counterpart.

Tyler Harlington

Winemaker

Four Feathers Wine Estates

Concrete gives the wine the weight and texture of a barrel fermentation, but rather than tasting like a barrel, the wine tastes like where it was grown.

Pax Mahle

Winemaker

Pax Wines

I love concrete fermenters for Quintessa because of its thermal properties because it helps us express our true terroir, and creating wines that have body and stabilized tannins. In particular, it is an insulator so we have a much more even changes in fermentation temperatures, it is gentler on the yeast, I feel, and I’m seeing greater extractions and results.

Rebekah Wineberg

Winemaker

Quintessa

...as the fermenting wine rolls through the tank (remember that both alcohol and CO2 are being produced during fermentation) there are no “dead” spots in the tank and the temperature of the fermentation is consistent throughout the egg as is sugar and chemical composition of the wine.

Charles G. Tsegeletos

Winemaker

Cline Cellars

Personnel-wise [the concrete egg tank] is a life-saver because nobody has to go do a pump-over or punch-down...

Leslie Mead Renaud

Winemaker

Martin Ray

[Concrete] adds more oxygen to the wine, allowing more dynamic fruit to come forward.

Jeremy Carter

Winemaker

Tarpon Springs

Column Two