Fruit-Forward • Pure Flavor • Enhanced Mouth-Feel

Why Concrete

Is The Right Choice

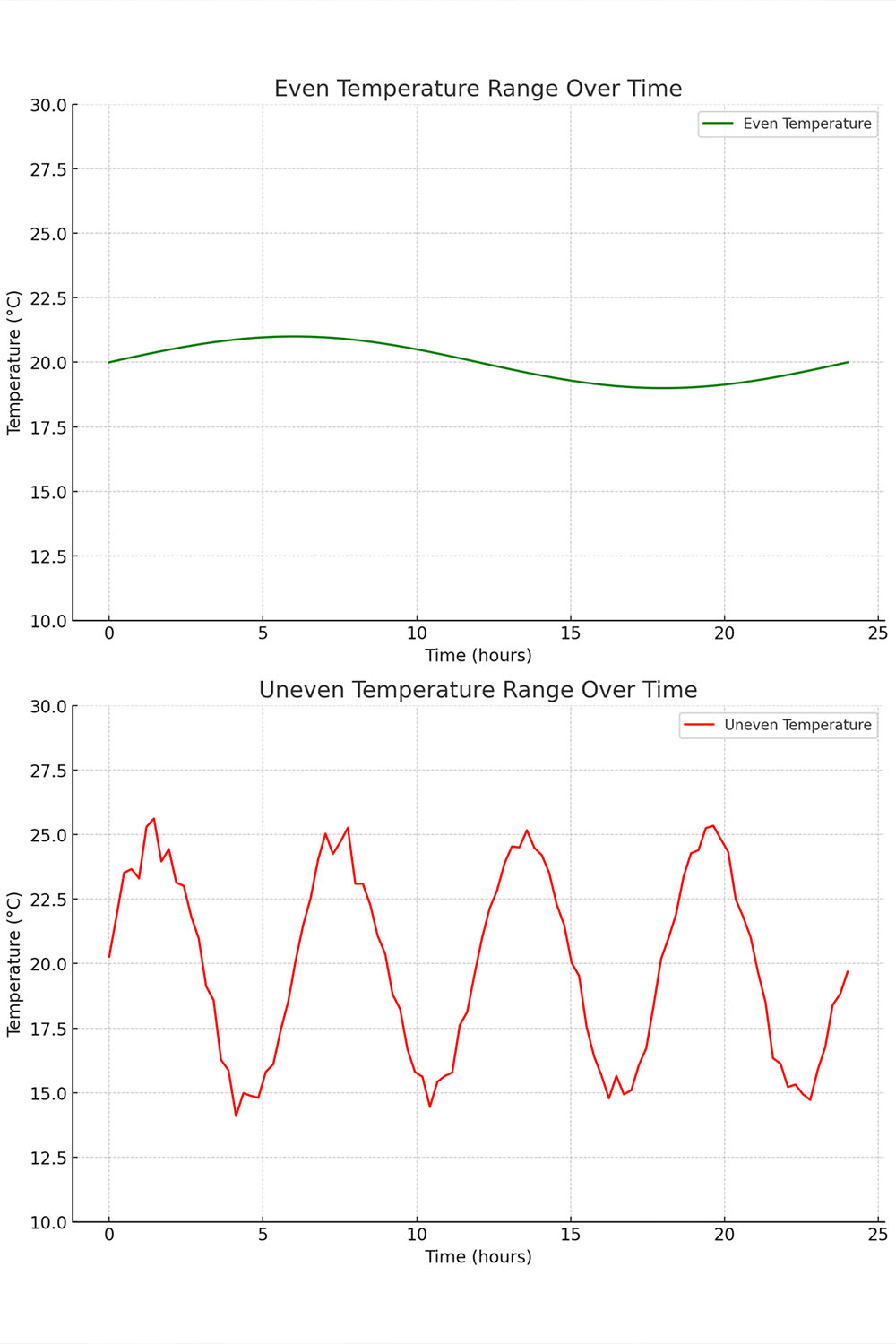

Concrete fermentation vessels offer a unique blend of tradition and innovation, delivering serious advantages to winemakers. Their natural thermal mass provides exceptional temperature stability, fostering a more even, controlled fermentation.

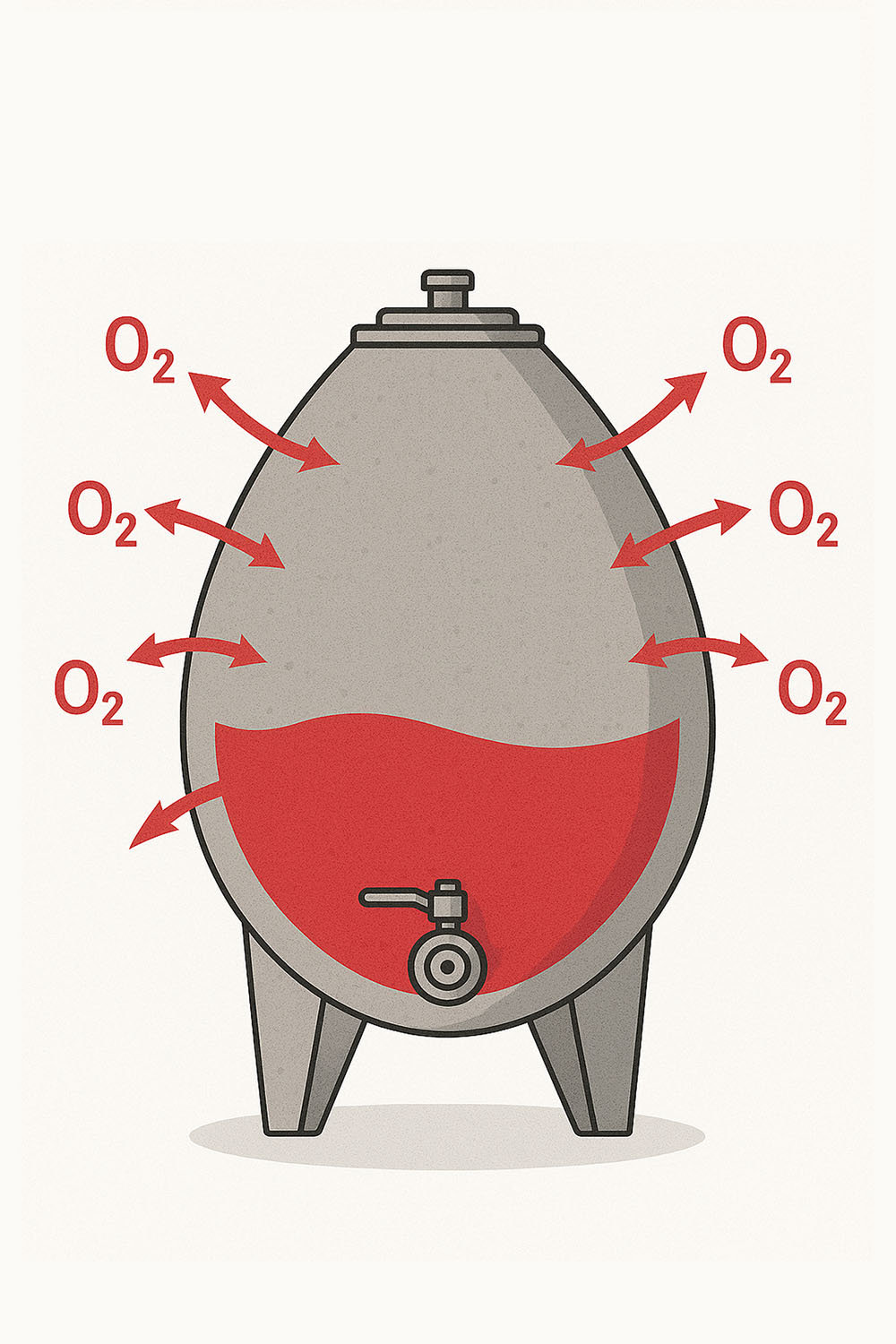

Organic shapes—like the egg or amphora—encourage natural fluid circulation, minimizing sediment buildup and enhancing flavor integration. Unlike stainless steel, concrete allows for gentle micro-oxygenation, which softens tannins and reveals the wine’s true terroir.

The result is a richer, more expressive wine, where varietal character shines through with depth and nuance. Concrete isn’t just a vessel—it’s a tool for crafting exceptional wine.

What A Difference

A Shape Makes

Concrete can be cast into any shape, offering winemakers both functional and expressive design options. Square and rectangular tanks maximize space efficiency and reduce cost per gallon—ideal for high-volume production.

But organic shapes like eggs and amphorae have no corners, encouraging natural fluid circulation that you can actually observe. This promotes a healthier fermentation process and, ultimately, produces better, more expressive wine.

Eco-Efficient &

Good for Wine

Concrete naturally insulates, maintaining a stable internal temperature regardless of external conditions. This thermal stability supports a slow, even fermentation without the temperature spikes that can overstimulate yeast. The result is a smoother, more controlled process that preserves the wine’s delicate balance. Concrete is equally well-suited for aging.

Sonoma Cast Stone takes this quality a step further with an innovative glycol system embedded within the tank walls, providing precision temperature control without compromising the tank’s clean, seamless design. It’s the perfect marriage of nature’s properties and modern engineering.

Micro-Oxygenation

And Expressive Wine

Fermenting wine in concrete allows subtle oxygen exchange, softening tannins and enhancing complexity—something stainless steel can’t provide.

Unlike oak, concrete imparts no additional flavors, letting the true character of the grape shine. This makes it ideal for winemakers seeking fruit-forward purity, balance, and a more expressive, terroir-driven wine without the influence of oak.

Unmask

The Fruit

For winemakers seeking purity of expression, concrete offers a truly neutral canvas. Unlike oak—even so-called “neutral” barrels, which inevitably impart lingering tones of wood and toast—concrete allows the wine to speak for itself. There’s no overlay of flavor, no masking of the fruit’s natural character.

Instead, the wine maintains its varietal clarity and a vivid sense of place, showcasing the terroir in full. Concrete does contribute a subtle minerality, but this is gentle and elegant, enhancing rather than altering.

The result is wine with unadulterated fruit flavor—vibrant, focused, and unmistakably honest in its origins.

But Can You Taste

The Difference?

At the inaugural Innovation + Quality conference, hosted by Wine Business Monthly, 400 top-tier winemakers gathered to explore how innovation can elevate ultra-premium wine production. Among the highlights was a blind tasting comparing wines fermented in oak, stainless steel, and concrete.

The purpose was to evaluate how each material influences flavor, texture, and purity. When the tasting concluded, it was clear: no official vote count was needed.

The overwhelming consensus favored the wine made in concrete—praised for its balance, clarity, and true expression of fruit—affirming concrete’s role as a game-changing vessel in the pursuit of quality winemaking.

Sonoma Cast Stone

50,000 sq-ft

Production Facility

For one perfect tank… or a hundred of them.

Get Pricing

Column Two